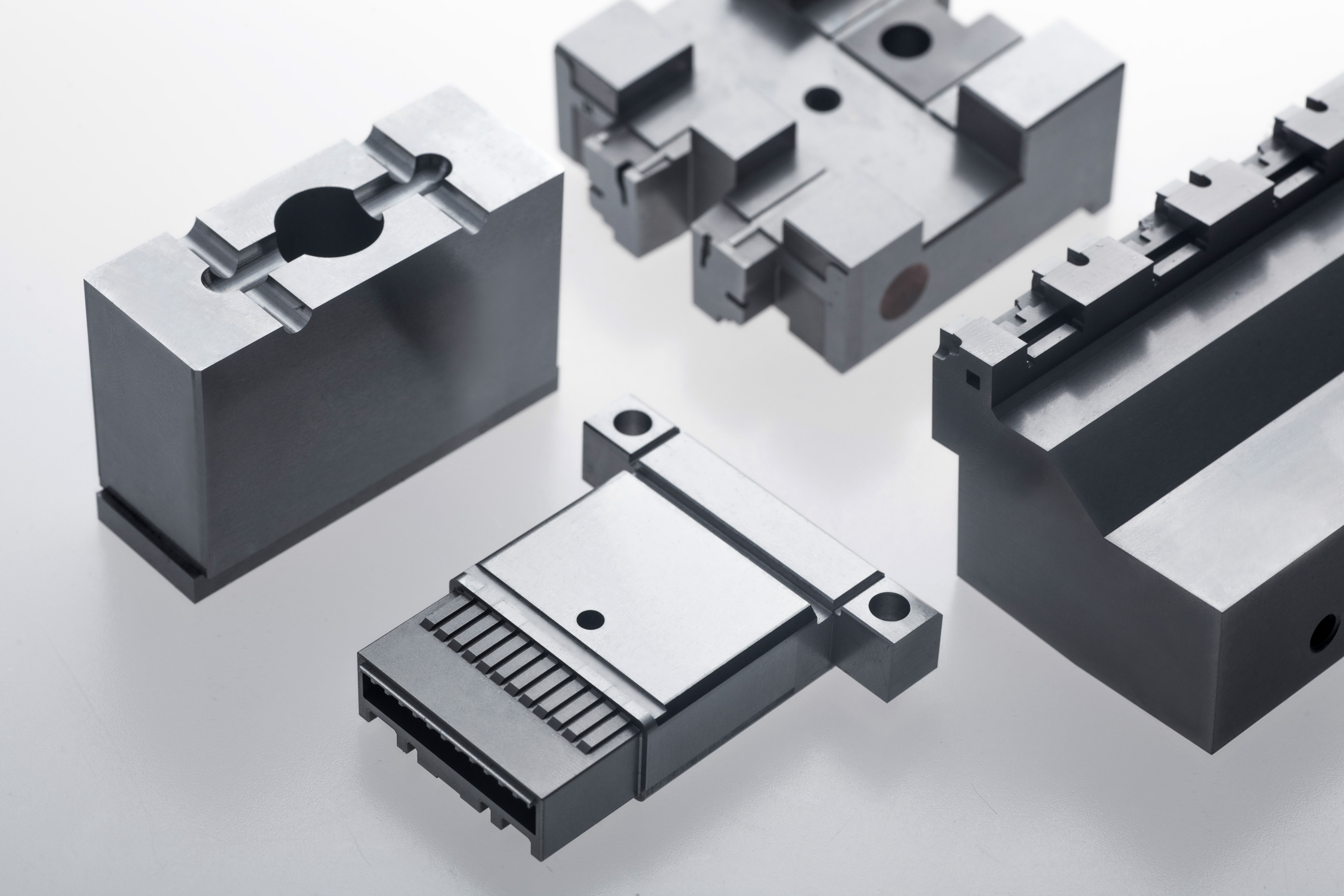

After years of continuous efforts and development, stamping die parts companies have passed reforms to improve their own strength. It is a good development opportunity to actively strive for the development opportunities in the mid- to high-end market, but in fact there is still a certain foundation. Heat-resistant and wear-resistant stamping die parts provide many manufacturers with more high-end machining operations. Let us share the role of stamping die parts in high-end machining.

1. Provide more services and form an industrial chain

At present, domestic private mold enterprises generally possess advanced equipment resources. The technical application of stamping die parts is relatively advanced. New technologies can be widely and quickly applied in the industry. From design and manufacturing to related material production and heat treatment, an industrial chain has been formed.

2. Reduce resource consumption and waste emissions

It is necessary to promote the pilot project of circular precision economy in China's stamping die parts industry, focusing on reduction, reuse and resource conversion, to reduce resource consumption and waste emissions, and actively implement preferential policies for comprehensive utilization of national resources.

3. Easily realize the processing of fine areas

The basic requirements for stamping die parts processing are to obtain high precision, smooth part surface quality, and fine areas that are easy to process. Stamping die parts can be adjusted to larger tolerances during semi-finishing, thereby saving calculation time. The tool selected is superior to the tool used for finishing, or the root is removed in advance to avoid tool collision at corners during finishing.

All in all,

stamping die parts have been found that in actual processing, especially in finishing, the output of PTP files when using fixed-axis milling will be greater. Another kind of circular interpolation method provided by high-quality stamping die parts greatly reduces things after processing, reduces the machine's pre-reading load, and can easily achieve high feed speed. Maintain a very high finish and surface quality.

skype

skype