How the

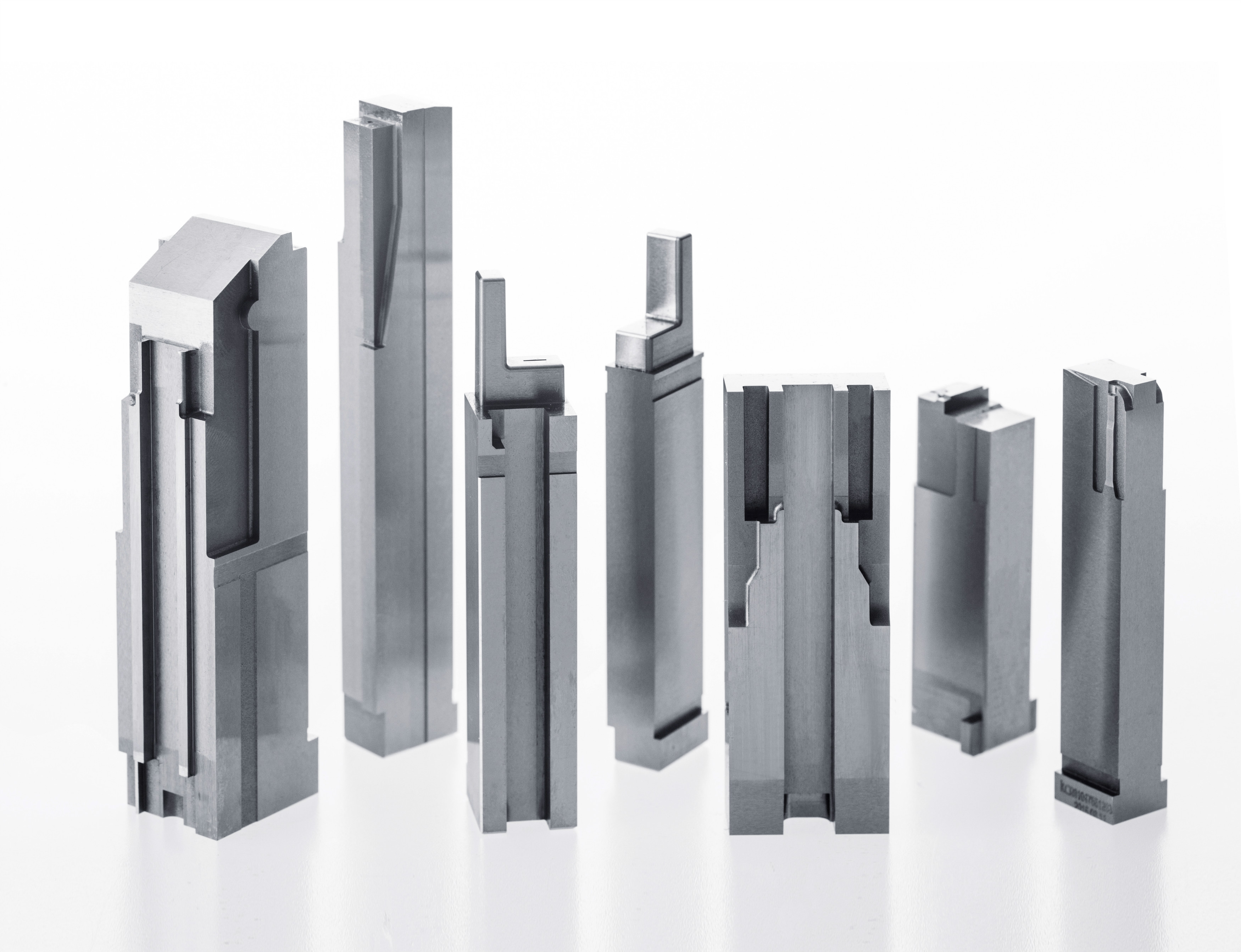

stamping die is assembled. After all parts of the stamping die are processed, assembly operations are required. When assembling, you must strictly follow the specifications. If you do not assemble as required, it is easy to damage the mold during trial and cause irreparable losses. The editor of stamping mold processing tells you the specific operation points as follows:

1. After the stamping die is assembled, first measure whether its overall height meets the design requirements. If there are heights, you should check the reasons carefully.

2 The clearance between the guide post and the guide sleeve should meet the design requirements, and all parts should be uniform.

3. After the guide column and the guide sleeve are turned into the upper and lower concave and convex molds, their axis lines must be perpendicular to the end surfaces of the concave and convex molds, and the end surfaces of the upper and lower concave and convex molds are parallel.

4. After the mold base is assembled, observe whether the upper mold base slides smoothly up and down along the guide post.

5. After the die handle is inserted into the upper die base, its axis line must be perpendicular to the end face of the punch, and its error should not exceed 0.05mm.

6. After the guide post is installed, it should normally be 1-2mm away from the lower end surface of the die mold base. If you choose the B guide sleeve, it should also be 1-2mm away from the upper end surface of the punch mold base.

7. The gap between the concave and convex molds is uniform and consistent, which meets the design requirements.

skype

skype