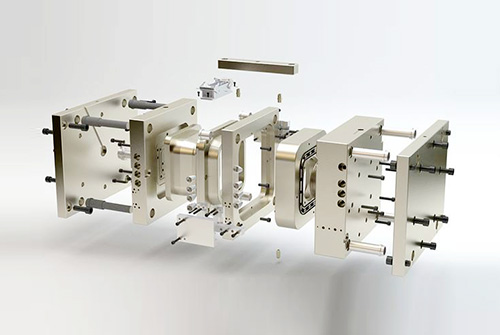

It usually takes about a month to open an

injection mold. The time required for complex molds is relatively long. Usually an injection mold is opened and a detailed review is required. The mold can only be opened after approval. After opening the injection mold, the mold needs to be tested. The following items are needed for injection mold manufacturing:

1. The cooling (water passage) in the mold is related to factors such as product size, shape, plasticity and holding time.

2. The roughness of the mold cavity should reach the "mirror level", otherwise the product is difficult to demold, and the product needs too much power to be damaged when the product is ejected. The roughness of the positioning pin, clamping surface and other components is specified by the standard.

3. The plastic mold should be rigid, otherwise it will deform when the mold is kept under pressure, resulting in "flashing" choosing a reasonable exhaust position and its control amount. Otherwise, the plastic is not filled and the product is "out of stock."

4. The injection molding road should be reasonably selected so that the material reaches each place evenly (the flow paths are equal), and there must be enough storage space to supplement the plastic during the shrinking process. Moreover, the shrinkage coefficient of each material is different, and the mold has a reasonable shrinkage rate.

5. The fixing method of the mold and the injection molding machine should be reasonable, reliable and firm, to prevent the displacement caused when the mold is closed and cause an accident. Disassembly is also very convenient. In addition, it is necessary to choose a reasonable demoulding method and select the appropriate position and number of ejector pins to ensure that the product is not damaged during the ejection process.

skype

skype