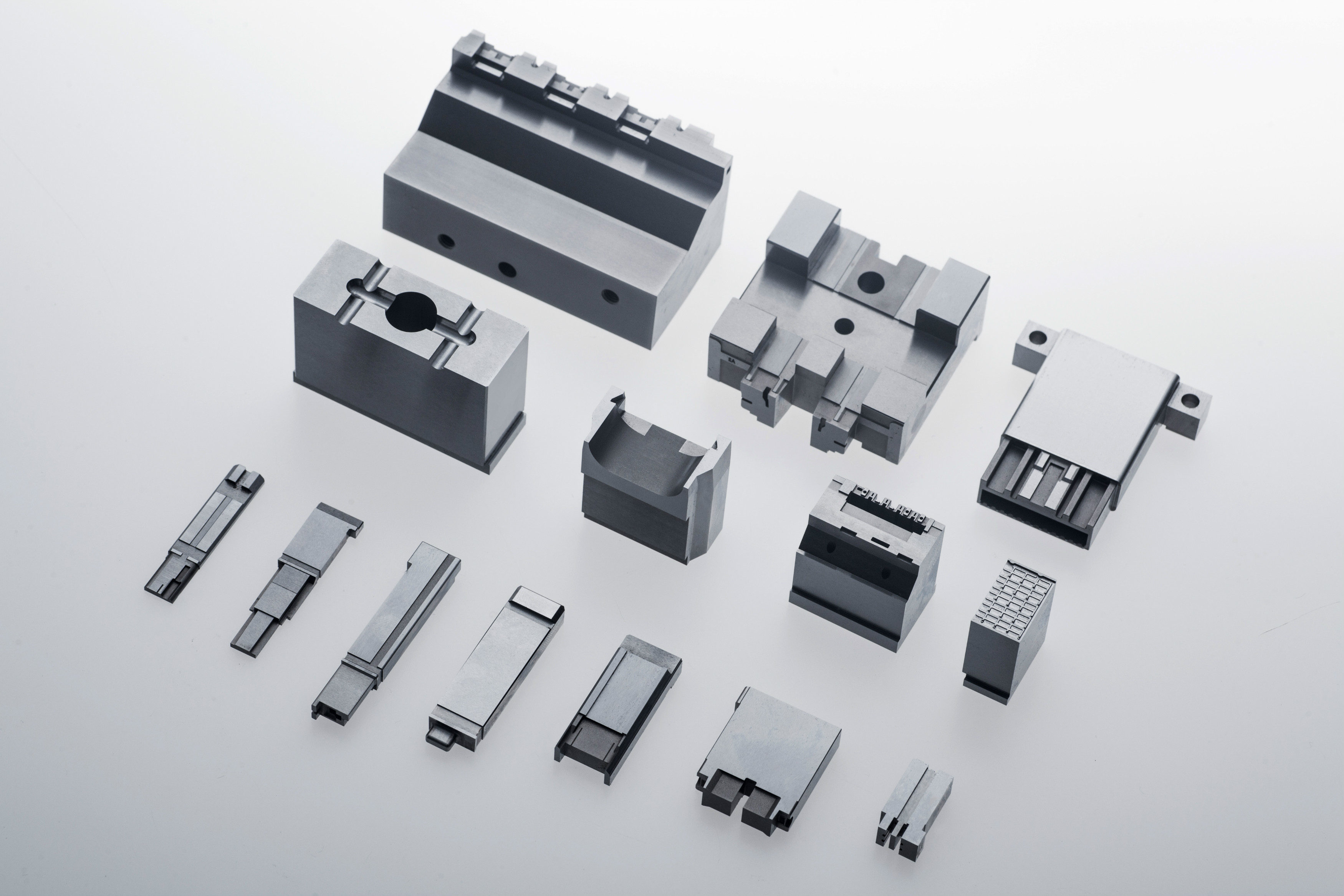

In order to improve the strength of the

stamping die, the final process of stamping die production requires finishing the surface of the die to eliminate small cracks on the surface of the die and prevent the cracks from being amplified and damaged during the strong impact of the press. The following editor of stamping die processing introduces several commonly used finishing methods of stamping dies.

1. Manual grinding and polishing, traditional mold surface processing methods, mainly rely on the experience and technology of the operator. Manual polishing is time-consuming and inefficient. Some more complex curved surfaces or joint grinding and polishing will be more difficult to handle.

2. Mechanical finishing-grinding. Commonly used grinding equipment includes surface grinders, internal and external cylindrical grinders, and tool grinders. In order to ensure accuracy, CNC method is generally used for processing. Choose the appropriate type of grinder according to the shape of different parts. The flat type grinder is used for the plate type parts. The internal and external cylindrical grinders or tool grinders are used for the arc and rotary parts.

3. Mechanical finishing-CNC milling machine. In this method, the stamping die surface processing method is fast and efficient, and the processing quality is good, except for the cavity with an internal acute angle and the extremely narrow and deep cavity, other aspects can be competent. It has become the mainstream technology of stamping die processing abroad, and my country is also actively developing.

skype

skype