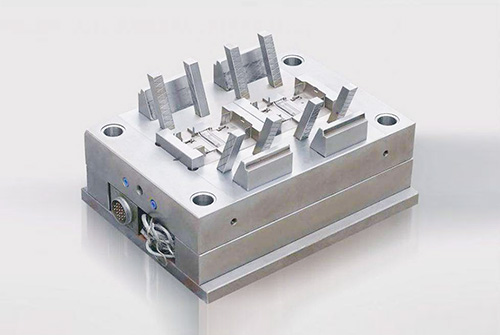

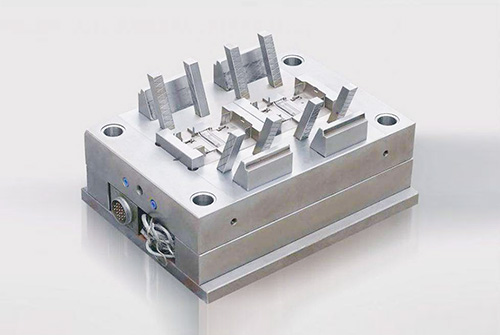

Precise plastic molds should be regularly maintained during use. If the product is found to be defective, the wear condition of each part of the plastic mold should be checked. If it needs to be repaired, it should be repaired. If it needs to be replaced, it should be replaced. In short, the precision plastic mold is not allowed to work. .

Common maintenance methods for precision plastic molds;

1, daily maintenance. Various moving parts such as thimble, row position, guide post, guide sleeve refueling, mold surface cleaning, water transporting, this is the daily maintenance of plastic mold production.

2. Regular maintenance. Regular maintenance, including daily maintenance, also requires the cleaning of the exhaust vents, trapping the black spots, adding exhaust, damage, and repairing the wear parts.

3, appearance maintenance. The outside of the mold blank is painted to avoid rusting; when the lower mold is used, the fixed mold should be coated with anti-rust oil; when the plastic mold is stored, it should be closed tightly to prevent dust from entering the cavity.

Under the normal operation of the injection molding machine and precision plastic mold, we need to test the various properties of the plastic mold, and measure the size of the finished plastic part. Through this information, we can determine the current state of the plastic mold and find the cavity and shape. Damage to the core, cooling system, and parting surface, etc., according to the information provided by the plastic parts, the damage state of the plastic mold and maintenance measures can be judged.

skype

skype