Stamping die is the main process equipment for stamping, and it is a key tool in industrial production. There are many factors affecting the service life of stamping dies. The failure of stamping dies is one. The main forms are wear failure, deformation failure, fracture failure and flaw failure. Below we make a specific introduction to these, I hope that everyone can understand this, and thus make corresponding improvement measures.

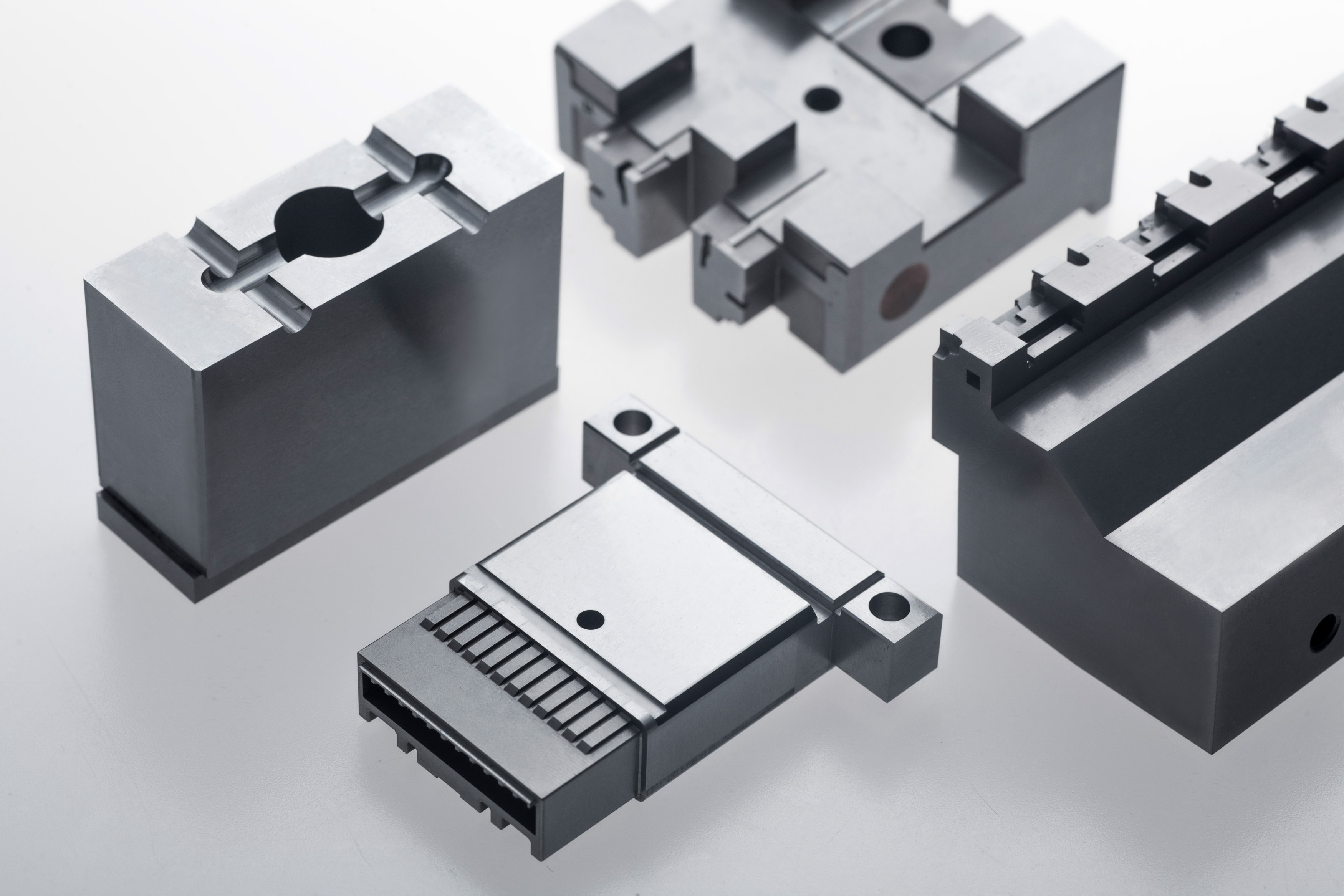

1 stamping equipment

The accuracy of stamping equipment (such as presses) and the impact of rigid on die life are extremely important. The precision of the stamping equipment is high, the rigidity is good, and the die life is greatly improved. For example, the complex silicon steel sheet die material is Cr12MoV, which is used on ordinary open presses, and the average regrind life is 1-3 million times. On the new precision press, the regrind life of the die can reach 6~120,000 times. Especially for small gap or gapless die, carbide die and precision die, it is necessary to select a press with high precision and good rigidity. Otherwise, the die life will be reduced, and the chess piece will be damaged in severe cases.

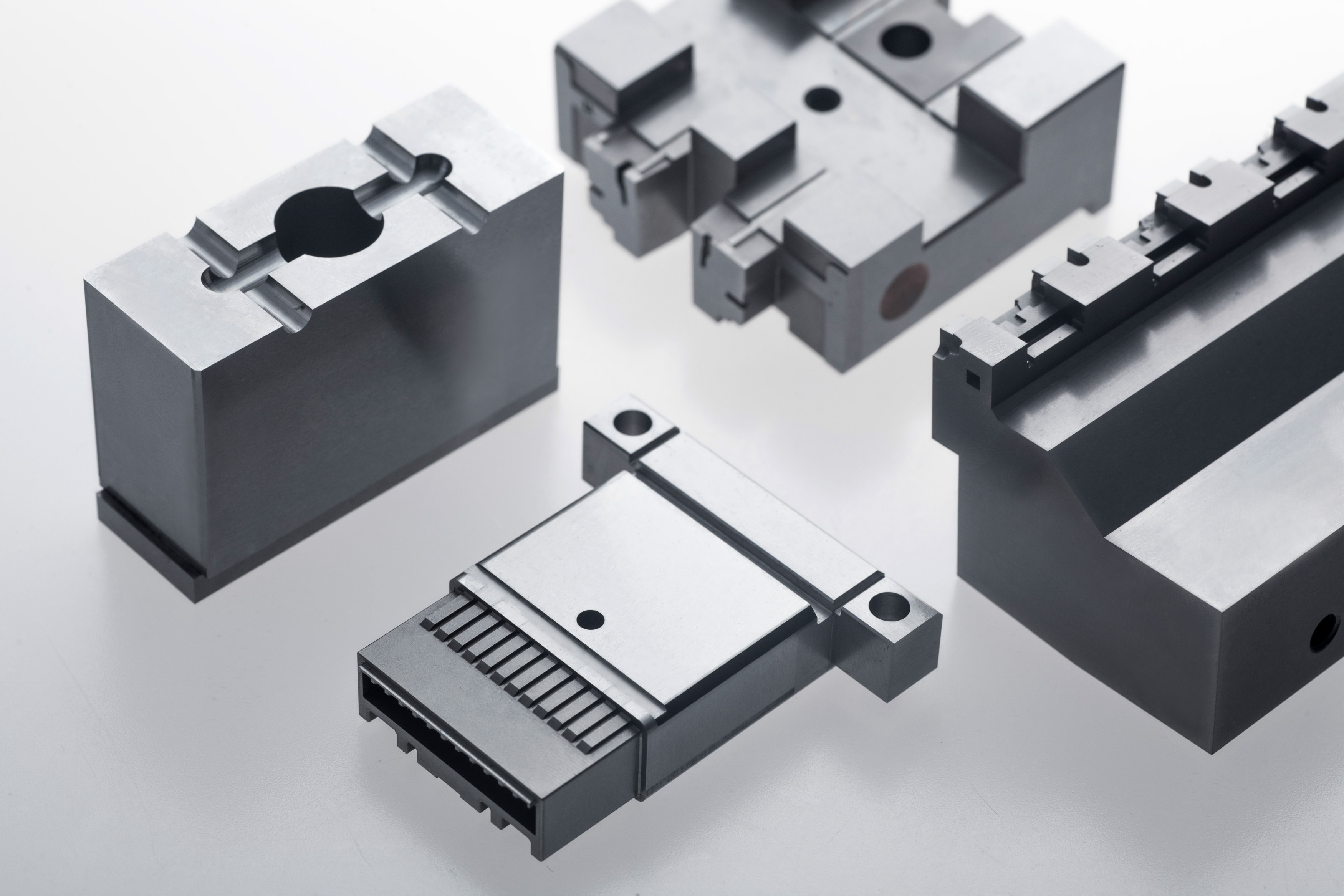

2 stamping die design

(1) Precision of the guiding mechanism of the mold. Accurate and reliable guiding, to reduce the wear of the working parts of the mold, to avoid the impact of convex and concave molds, especially the gapless and small gap blanking die, composite die and multi-station progressive die are more effective. In order to improve the life of the mold, it is necessary to correctly select the guiding form and determine the accuracy of the guiding mechanism according to the requirements of the nature of the process and the accuracy of the parts. In general, the accuracy of the guiding mechanism should be higher than that of the convex and concave molds.

(2) Geometric parameters of the die (convex, concave die). The shape of the convex and concave molds, the fit clearance and the fillet radius not only have a great influence on the forming of the stamping part, but also have a great influence on the wear and life of the mold. For example, the matching clearance of the mold directly affects the quality of the blank and the life of the mold. For higher precision requirements, a smaller gap value should be selected; otherwise, the gap can be appropriately increased to improve the life of the mold.

3 stamping process

(1) Raw materials for stamped parts.

In actual production, due to the excessive thickness tolerance of raw materials for external pressure parts, fluctuations in material properties, poor surface quality (such as rust) or unclean (such as oil stains), the wear of the working parts of the mold is intensified, and it is easy to collapse. as a result of.

To this end, you should pay attention to:

1 Use as much as possible of the stamping process of raw materials to reduce the stamping deformation force;

2 Before stamping, the grade, thickness and surface quality of the raw materials should be strictly checked, and the raw materials should be wiped clean. If necessary, the surface oxides and rust should be removed.

3 According to the stamping process and the type of raw materials, softening treatment and surface treatment can be arranged as necessary, and a suitable lubricant and lubrication process can be selected.

(2) Layout and edging.

Unreasonable reciprocating feed patterning and too small edge values often cause sharp wear of the mold or bruises on the convex and concave molds. Therefore, while considering the improvement of material utilization, it is necessary to reasonably select the layout method and the edge value according to the processing batch size, quality requirements and mold matching gap of the parts to improve the life of the mold.

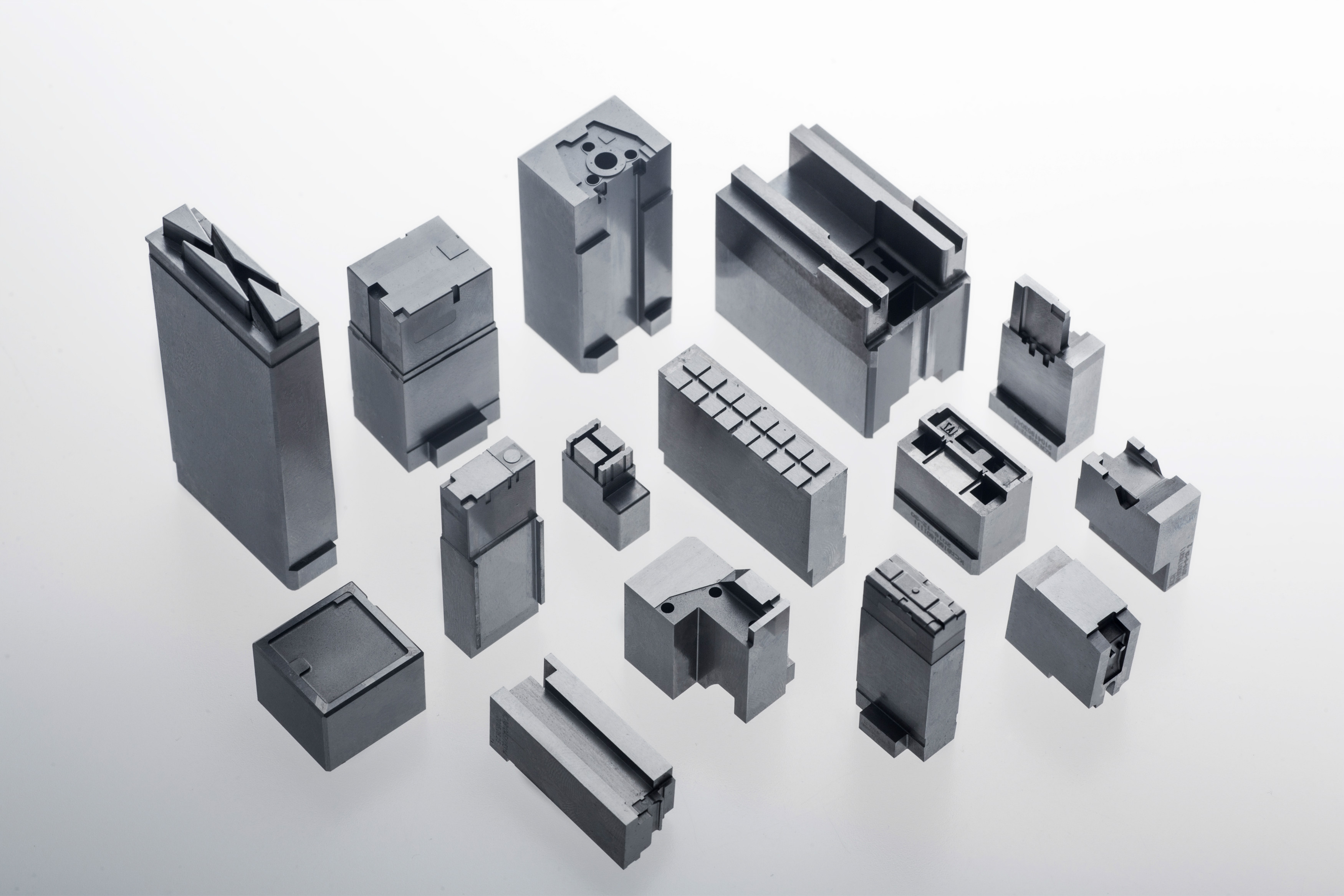

4 stamping die material

The influence of mold materials on mold life is a comprehensive reflection of material type, chemical composition, microstructure, hardness and metallurgical quality. Die life of different materials often varies.

To this end, two basic requirements are imposed on the material of the die working parts:

1 The material should have high hardness (58~64HRC) and high strength, high wear resistance and sufficient toughness, small heat treatment deformation and certain thermal hardness;

2 process performance is good. Die manufacturing parts manufacturing process is generally more complicated. Therefore, it is necessary to have adaptability to various processing processes such as forgeability, machinability, hardenability, hardenability, quench crack sensitivity, and grinding processability. Generally, according to the material characteristics of the stamping parts, the production batch, the precision requirements, etc., the mold materials with excellent performance are selected, taking into consideration the processability and economy.

The material of the Toolox series is a kind of pre-hard new tool steel with high toughness, high wear resistance and almost no internal stress. The processing stability is particularly good. Compared with the corresponding materials under the same conditions, the processing efficiency is improved by about 20%. It also has very high purity, very fine grain size, very low S and P content, low carbide content and very uniform. Due to the special composition design, Toolox series materials have excellent surface treatment properties, among which The surface hardness of Toolox44 after nitriding can reach above HRC65, the surface hardness of Toolox40 can reach above HRC62, and the surface hardness of Toolox33 can reach above HRC58. The depth is up to 1.8mm. Therefore, TOOLOX series materials have special advantages in stamping dies.

skype

skype